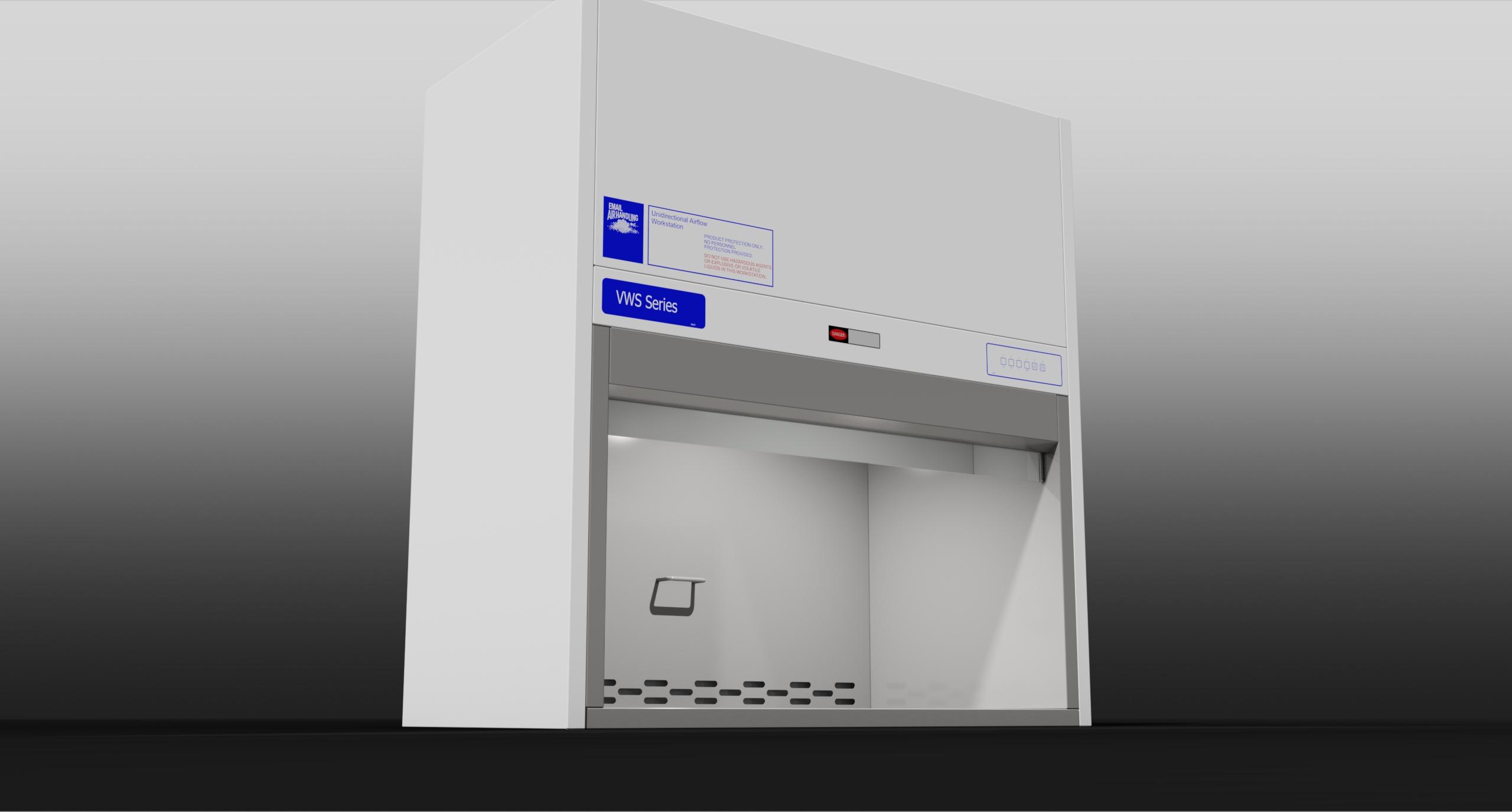

Vertical Laminar Flow Cabinets VWS

The Australian Made VWS (Vertical flow) Laminar Flow Series cabinets are designed to provide a high degree of protection for process products and apparatus in laboratory and production facilities.

Many critical applications in the medical, pharmaceutical, scientific and electronics fields demand an ultra-clean work environment that is free from biological and particulate contamination.

Overview

The VWS series Laminar Flow Cabinets are expertly designed to provide smooth, vertical airflow through the work zone, ensuring optimal performance and safety. The blower fan and its strategic mounting enhance airflow, while the deeper rear plenum ensures unobstructed airflow to the HEPA filter face. This design results in quieter operation, reduced vibration, and an extended service life for the HEPA filter.

Key Features:

- Optimised Airflow: Vertical laminar airflow maximises efficiency and minimises turbulence.

- Quiet Operation: Fans and filter plenums are designed for quiet performance with low vibration levels.

- High-Quality Construction:

- Cabinet Housing: Constructed from locally sourced steel with a high-quality powder-coated finish, resistant to solvents, alkalis, and acids.

- Work Area: Fully stainless steel with inward folds to avoid sharp edges.

- HEPA Filter Protection:

- Removable Metal Screen: Washable and protects the HEPA filter from mechanical damage.

- Clyde-Apac Microseal HEPA Filters: Manufactured to AS 4260 standards, each filter is individually tested and certified leak-free according to AS 1807.6. A test label with an extract of the test report is affixed to each filter.

- Pre-Filter System:

- Extend HEPA Filter Life: The prefilter captures at least 90% of particles 5 microns and larger.

- Service Indicator: A warning light signals the need for prefilter maintenance.

- Fan Control: Direct-drive fan regulated by a speed controller to maintain consistent airflow throughout the filter’s life.

- User-Friendly Features:

- Low-Voltage Touch Control Panel: Located on the front of the cabinet for easy access.

- Lighting: Glare-free lamps provide a minimum intensity of 650 lux at the work surface.

- Application Scope: Designed for work with non-hazardous materials, providing product and experiment protection but not personnel protection.

Typical Applications:

- Aseptic Dispensing: Ensuring sterility and precision.

- Electronics and Optics Assembly: Providing a clean environment for delicate components.

- Cell Culturing: Maintaining a sterile area for cell growth and experimentation.

- Media Pouring: Ensuring contamination-free media preparation.

- Medical Device Preparation: Sterile environment for the preparation of medical tools and devices.

- Sterility Testing: Providing a contaminant-free environment for accurate sterility testing.

Important Considerations: For applications that require personnel and environmental protection from hazardous aerosols, consider using Clyde-Apac Class I or Class II biological safety cabinets or cytotoxic drug safety cabinets, as appropriate.

The VWS Series Laminar Flow Cabinets are ideal for laboratories and cleanrooms requiring a controlled, non-hazardous environment. Their advanced features and robust construction make them a reliable choice for ensuring the integrity of sensitive processes and products.

Technical Data

-

BrandAES Environmental

-

Models AvailableFour

-

Sizes900/1200/1500/1800mm

-

Electrical2A/230V

-

Filter TypeHEPA

-

Complies WithAS 2252.6

Support & FAQs

At Thermoline, we strive to supply helpful customer support to ensure that you get the most out of our products. We are committed to providing whatever support our customers need, wherever they are in the world. If you can't find your solution in the below FAQs or Knowledge Base, please contact our friendly support team.

- Where are the clean air cabinets supplied by Thermoline manufactured?

- All of the cabinets we supply are Australian Made by AES Environmental. AES has several manufacturing locations in Australia, and all of the Laminar Flow and High-Efficiency Filtration products are produced in their Minto, NSW facility.

- What is a laminar flow cabinet used for?

- A laminar flow cabinet keeps a controlled work surface for applications requiring a sterile work space whereas contaminant access is being prevented by a constant filtered airflow across the surface.

- Why might a UV light be used in laminar flow cabinets?

A UV light (ultraviolet light) can be used in a laminar flow cabinet for decontamination purposes. UV light has the ability to kill a variety of microorganisms, including bacteria, viruses, and fungi, by disrupting their DNA or RNA.

In a laboratory setting, a UV light can be used in a laminar flow cabinet to reduce the risk of contamination of samples or equipment. This is particularly useful in sensitive experiments, such as cell cultures or microbiological assays, where even a small amount of contamination can cause significant problems.

- Can Thermoline arrange installation and commissioning of my cabinet?

- Yes. Our suppliers have service divisions in most Australian states and territories and relies on qualified partners for other geographical locations. Each team is capable of providing on-site installation and NATA certification.