As the world of non-destructive testing (NDT) continues to advance, industries are constantly seeking innovative solutions to improve inspection processes. The drying phase is a crucial step in the Fluorescent Penetrant Inspection (FPI) process. Using a specialised NDT Drying Oven has proven instrumental in achieving reliable results. In this article, we will delve into the significance of NDT Drying Ovens in the context of FPI, focusing on meeting the stringent standards outlined by ASTM E1417.

Understanding Fluorescent Penetrant Inspection:

Fluorescent Penetrant Inspection is a widely utilised NDT method for detecting surface-breaking defects in materials, particularly in critical industries such as aerospace, automotive, and manufacturing. This method involves applying a fluorescent dye to the surface of a test object, allowing it to penetrate into surface-breaking defects through capillary action. After the application, the excess penetrant needs to be removed, and the remaining penetrant is made visible through the application of a developer.

The Role of Drying in FPI:

Drying is a crucial step in the FPI process as it ensures the removal of excess penetrant before applying the developer. Inadequate drying can lead to false indications, compromising the accuracy of the inspection. This is where NDT Drying Ovens come into play, providing a controlled environment for efficient and thorough drying of the test object.

ASTM E1417 Standard Compliance:

ASTM E1417 is the standard practice for liquid penetrant testing, providing guidelines for the proper execution of the FPI method. In this context, the drying phase is addressed in detail, emphasising the need for a controlled drying environment to achieve reliable and repeatable results. NDT Drying Ovens designed for FPI must adhere to these standards to ensure the integrity of the inspection process.

Key Features of NDT Drying Ovens for FPI:

- Temperature Control: NDT Drying Ovens must have precise temperature control capabilities to maintain the recommended drying temperature specified in ASTM E1417.

- Uniform Airflow: Ensuring uniform airflow is crucial to prevent uneven drying and to guarantee consistent results across the entire surface of the test object.

- Drying Time Management: The oven should be equipped with programmable timers to facilitate accurate drying time management, aligning with ASTM E1417 recommendations.

- Material Compatibility: The construction materials of the oven must be compatible with the penetrant materials used in the FPI process to prevent contamination.

- Safety Features: NDT Drying Ovens should incorporate safety features, such as temperature alarms and emergency shutdown mechanisms, to ensure operator safety and prevent damage to the test object.

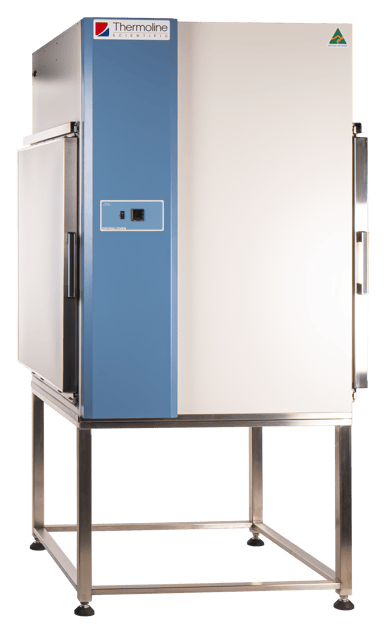

Thermoline recently manufactured a custom-built drying oven to meet ASTM E1417 for a global company in the aerospace industry, specifically manufacturing wheels and brakes. The brief was to supply an oven that would sit along a conveyor line with their product entering the oven on one side ‘wet’, then exiting the other side having been dried inside the oven. The temperature requirement was 71°C, +/- 8°C in the workspace as per the requirements in ASTM E1417 and to have stainless steel rollers capable of handling up to 75kgs. Slide-out doors were required on each side to move on heavy-duty roller tracks, ensuring long-lasting reliability. Finally, the oven had to be on a sturdy frame to line up with the existing conveyor, allowing a seamless transition into and through the oven.

The result was a proudly Australian Made drying oven within budget and delivered on time.

“Could you please pass on to your design and production teams that I am very impressed with the drying oven. Both design and quality of manufacture look great.”

Peter L.

Managing Director

Conclusion:

In conclusion, integrating a specialised NDT Drying Oven into the Fluorescent Penetrant Inspection process significantly contributes to the reliability and accuracy of defect detection. Meeting the standards outlined in ASTM E1417 is imperative for ensuring consistent and high-quality inspection results. As industries continue to prioritise safety and quality, the utilisation of NDT Drying Ovens that comply with ASTM standards emerges as a pivotal step in enhancing overall inspection processes.

If you have specific requirements for an oven that meets ASTM E1417 or any other standards, we would be delighted to discuss your needs with you. Please feel free to contact us so that we can provide you with the perfect solution.