Class 8 Corrosive Substance Storage Cabinet SC8

Two ranges of corrosive storage cabinets are available - high-density polyurethane and a steel 2-PACK corrosion-free polyurethane finish.

These ranges are manufactured from 25% heavier materials than the minimum requirement and are double-walled sheet steel construction with a 40mm thermic air barrier.

Overview

The SAFE-T-STORE storage cabinets for corrosive substances offer a range of capacities from 15L to 850L, featuring the patented SAFE-T-CLOSE sequential closing system. These cabinets provide everyday safe storage for most Dangerous Goods and comply fully with legislative construction requirements, making them a well-respected performer across all industries.

Steel Models:

- Double-Walled Construction: Made from sheet steel with a 40mm thermic air barrier for enhanced protection.

- High Capacity Sump: Liquid-tight sump to effectively contain spills.

- Self-Closing Doors: Close-fitting doors with two-point catches, capable of being opened from within.

- Ventilation: Built-in flash arrestors and vent openings for mechanical ventilation systems.

- Adjustable Shelving: Strong, fully adjustable shelving perforated for free air movement with 100mm adjustment increments.

- Sequential Door Closing: Stainless steel pins with continuous hinging for strength and reliability.

- Durable Finish: State-of-the-art powder coat finish for high durability and performance.

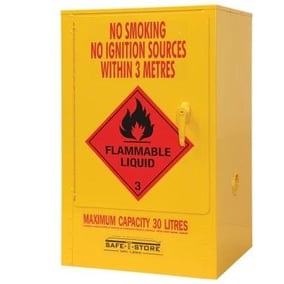

- Safety Signage: Distinct safety signs and directions comply with AS 1216 and AS 1319.

Polyethylene Models:

- High Capacity Sump: Liquid-tight spill containment sump for effective spill management.

- Self-Closing Doors: Close-fitting doors that do not open inward and can be opened from within the cabinet.

- Corrosive-Resistant Latch: No metallic components for maximum corrosion resistance.

- Adjustable Shelving: Strong, fully adjustable shelving perforated for free air movement at 100mm increments.

- UV-Stabilized HDPE Construction: Fully welded polyethylene construction with optional vent openings and flash arrestors for mechanical ventilation systems, ensuring high durability and performance.

- Safety Signage: Complies with AS 1216 and AS 1319.

Compliance and Safety:

- AS 3780:2008 Compliance: Designed and manufactured in full conformance to AS 3780:2008 - The storage and handling of corrosive substances.

Applications:

- Laboratories: Safe storage for corrosive chemicals and substances.

- Industrial Facilities: Secure containment for corrosive materials used in manufacturing processes.

- Workshops: Safe storage for corrosive substances and cleaning agents.

- Educational Institutions: Ensures safe handling and storage of corrosive chemicals in school and university labs.

Choose Thermoline's SAFE-T-STORE storage cabinets for corrosive substances to ensure robust, compliant, and reliable storage solutions. Built to withstand harsh conditions while meeting the highest safety standards, these cabinets are the ideal choice for safely managing corrosive substances in your workplace.

Technical Data

-

BrandStoremasta

-

Capacity15L - 850L

-

Models AvailableTwenty +

-

ElectricalN/A

-

Complies WithAS 3780:2008

Support & FAQs

At Thermoline, we strive to supply helpful customer support to ensure that you get the most out of our products. We are committed to providing whatever support our customers need, wherever they are in the world. If you can't find your solution in the below FAQs or Knowledge Base, please contact our friendly support team.

- How and where should I store corrosive substances?

Storing corrosive substances requires special care and attention in order to minimize the risk of accidents and to ensure the safety of workers and the environment. Here are some general guidelines for storing corrosive substances:

-

Location: Store corrosive substances in a designated area, away from areas with high pedestrian or vehicle traffic. This will help to minimize the risk of accidents and to prevent damage to other materials.

-

Container: Store corrosive substances in their original containers, or in containers that are specifically designed for storing corrosive substances. Ensure that the containers are properly labeled and that any warning symbols or labels are clearly visible.

-

Ventilation: Store corrosive substances in a well-ventilated area to prevent the buildup of toxic fumes or vapors. A ventilation system, such as a fume hood or chemical storage cabinet, may be necessary in some cases.

-

Segregation: Store corrosive substances separately from flammable or combustible liquids, as well as from food, feed, or pharmaceutical products. This will help to minimize the risk of chemical reactions or contamination.

-

Security: Store corrosive substances in a secure area to prevent unauthorized access or theft. Ensure that the storage area is locked and that access is restricted to authorized personnel only.

In addition to these general guidelines, it is also important to follow any specific regulations or guidelines that apply to the storage of corrosive substances in your area.

-

- Do I need a corrosive substances storage cabinet?

Whether or not you need a corrosive substances storage cabinet will depend on the specific requirements of your workplace and the type and volume of corrosive substances you are storing. Here are some factors to consider:

-

Volume: If you are storing a large volume of corrosive substances, a storage cabinet may be necessary to ensure proper segregation and containment.

-

Hazard level: If the corrosive substances you are storing pose a high hazard to workers and the environment, a storage cabinet may be necessary to minimize the risk of exposure and to ensure proper containment in the event of a spill or release.

-

Regulations: Depending on your location and the type of industry you are in, there may be specific regulations or guidelines that require the use of a storage cabinet for corrosive substances.

-

Space: If you have limited space for storage, a cabinet can help to maximize the use of available space and minimize the risk of accidental releases.

In general, if you are storing a large volume of corrosive substances, if the substances pose a high hazard, if there are specific regulations or guidelines requiring the use of a storage cabinet, or if space is limited, a corrosive substances storage cabinet may be necessary.

If you are unsure whether or not a storage cabinet is required for your workplace, it is recommended to consult with a specialist or to contact relevant regulatory agencies for guidance.

-

- What is a corrosive substance?

A corrosive substance is a material that can cause severe damage or destruction to other materials through chemical reactions. Corrosive substances are typically acidic or alkaline in nature, and they can eat away at or dissolve other materials, such as metals, plastics, and organic matter. Corrosive substances are volatile substances that destroy body tissue as soon as they make contact with exposed skin, eyes, respiratory tract, making the safe storage of such substances crucial.

Examples of common corrosive substances include sulfuric acid, hydrochloric acid, nitric acid, and sodium hydroxide. These substances are commonly used in industrial processes and can be found in a variety of settings, including laboratories, manufacturing facilities, and storage facilities.

- What is chemical storage cabinet?

- A chemical storage cabinet is a specialized cabinet designed to store chemicals safely. It features shelving or drawers made of chemical-resistant materials, a tightly sealed door, and may have additional safety features such as a ventilation system, and is designed to meet specific safety and regulatory standards.