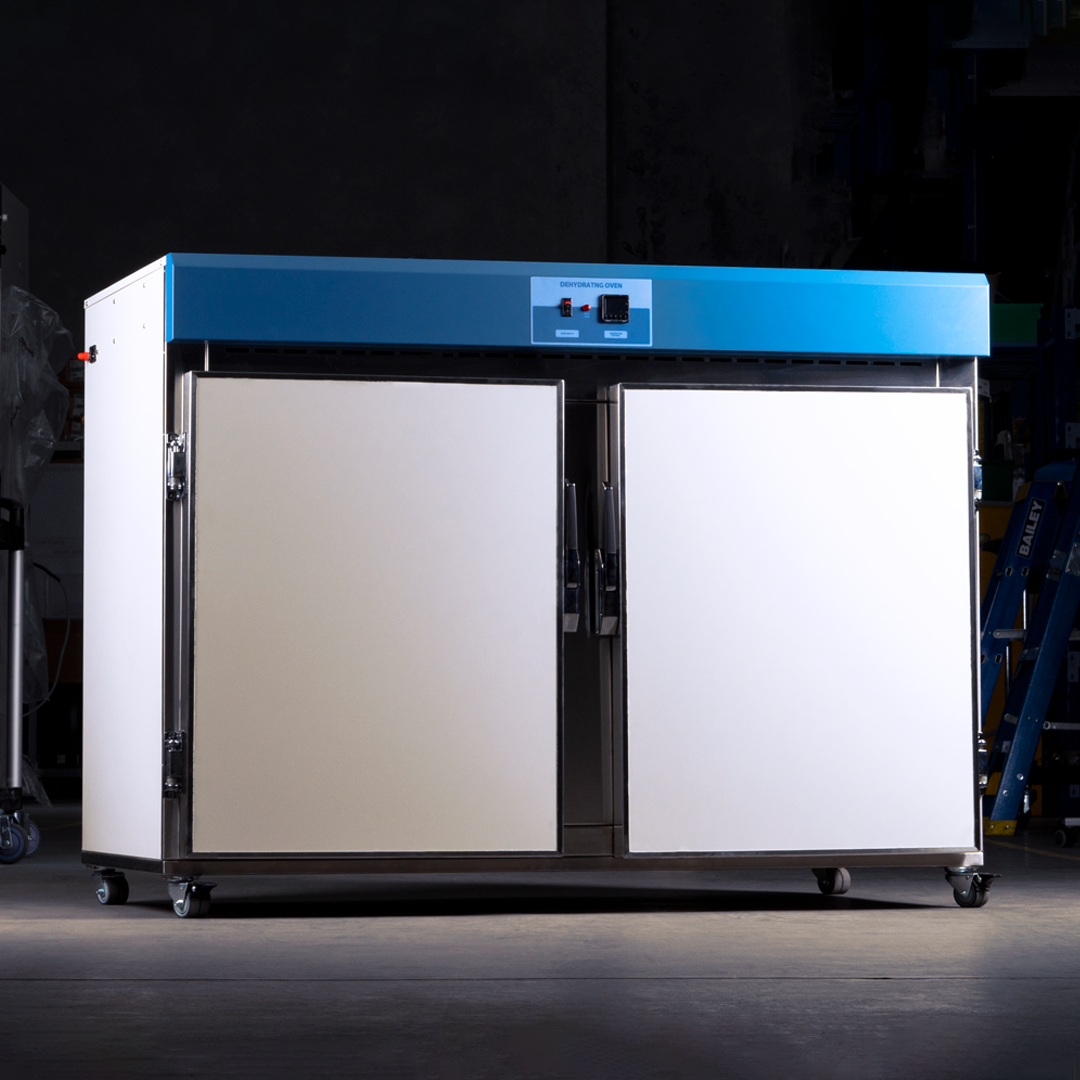

Drying Ovens TD (Drying)

Thermoline's benchtop and floor standing drying ovens are designed and manufactured in Australia for all laboratory and industrial functions.

The Thermoline drying oven is a type of laboratory oven used for drying, sterilizing, and heating various materials and samples commonly used in scientific research, medical, and industrial settings.

Which oven is right for me?Overview

The Thermoline drying oven range has been trusted by all industries for over 50 years. These ovens are the industry standard, and no other oven on the market offers the combination of quality, reliability, and durability that these Australian-made ovens provide.

Key Features:

- High-Grade Heating Elements: The Thermoline drying oven uses high-grade Incoloy heating elements controlled by digital PID controllers to deliver heat to the chamber.

- Uniform Temperature Maintenance: Industrial-type fan motors circulate warm air, maintaining uniform temperatures and ensuring fast recovery after door openings.

- Corrosion Resistance: Internal liners are manufactured from 316 marine grade stainless steel, along with stainless steel open wire shelving, providing superior corrosion and rust resistance.

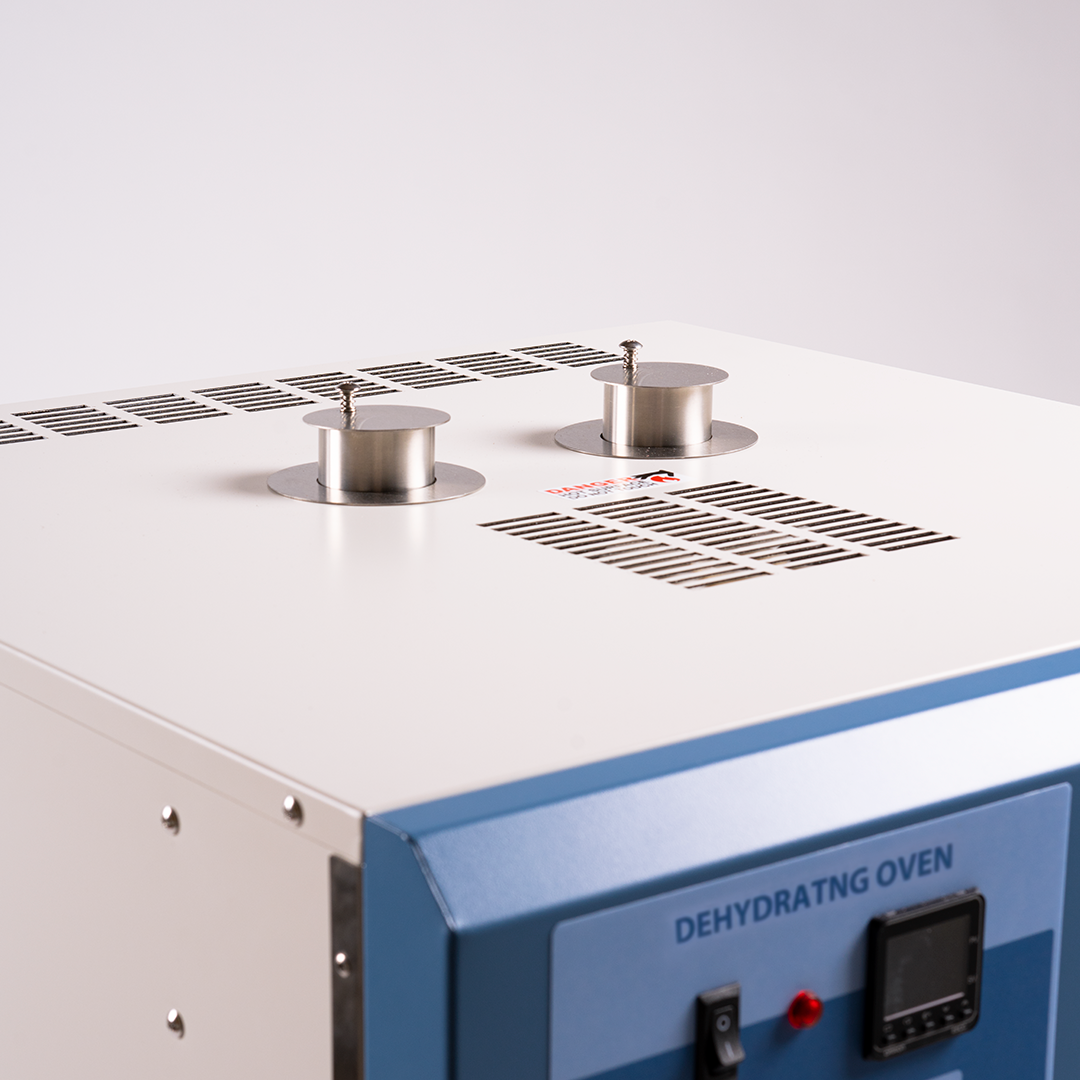

Air Flow System:

These fan-forced dehydrating ovens feature a horizontal air flow system that ensures dry heated air is directed across each shelf space, effectively drying samples anywhere inside the oven. Heated air is blown down the rear of the oven and then forced over the shelf spaces via a perforated rear wall. Moist air is vented outside the oven through a top porthole, preventing moisture buildup. Internal air flow can be regulated by adjusting the top ventilation ports.

Benefits:

- Exceptional Durability: Built with high-quality materials and advanced engineering, Thermoline drying ovens are designed to last, offering dependable performance for years.

- Consistent Performance: The advanced air flow system and industrial fan motors ensure uniform heating and quick temperature recovery, providing consistent and reliable results for all drying applications.

- Superior Corrosion Resistance: The use of 316 marine grade stainless steel and stainless steel shelving ensures that the ovens resist corrosion and rust, even in the most demanding environments.

Thermoline drying ovens are the ultimate solution for industries seeking high-quality, reliable, and durable drying ovens.

Thermoline laboratory drying ovens are versatile and essential tools for various applications across multiple industries. These ovens provide precise temperature control and uniform heat distribution, making them ideal for a wide range of laboratory and industrial processes.

Key Applications:

1. Sample Drying:

- Moisture Content Analysis:

- Drying samples to determine their moisture content accurately, crucial for quality control in food, pharmaceuticals, and agricultural industries.

- Soil and Sediment Drying:

- Removing moisture from soil and sediment samples for environmental and geotechnical analysis.

2. Sterilization:

- Glassware and Instrument Sterilization:

- Sterilizing laboratory glassware, metal instruments, and other heat-resistant materials to ensure a contamination-free environment.

- Disinfection:

- Using dry heat to disinfect various laboratory items that cannot be sterilized using autoclaves or chemical disinfectants.

3. Material Testing:

- Aging and Durability Testing:

- Simulating long-term environmental conditions to test the aging and durability of materials like plastics, rubber, textiles, and metals.

- Thermal Stability Testing:

- Assessing the thermal stability of materials by exposing them to elevated temperatures for specified periods.

4. Sample Preparation:

- Pre-Treatment of Samples:

- Drying samples before chemical analysis, ensuring that no moisture interferes with the analytical results.

- Ash Content Determination:

- Removing organic components by incinerating samples to determine the ash content, commonly used in food and agricultural testing.

5. Evaporation:

- Solvent Evaporation:

- Removing solvents from chemical solutions and mixtures, a common procedure in chemical synthesis and pharmaceutical manufacturing.

- Concentration of Samples:

- Concentrating solutions by evaporating excess solvents, crucial in biochemical and molecular biology research.

6. Curing and Polymerization:

- Resin and Polymer Curing:

- Providing the necessary heat for the curing and polymerization of resins, adhesives, and other polymer-based materials.

- Paint and Coating Drying:

- Drying and curing paints and coatings to ensure proper adhesion and finish.

7. Thermal Processing:

- Annealing:

- Heating materials to remove internal stresses and improve their mechanical properties, commonly used in metallurgy and materials science.

- Heat Treatment:

- Applying controlled heat to alter the physical and chemical properties of materials, enhancing their performance and durability.

Industries Benefiting from Thermoline Laboratory Drying Ovens:

- Pharmaceuticals:

- Drying and sterilizing equipment, preparing samples, and conducting stability testing.

- Food and Beverage:

- Moisture content analysis, sample preparation, and quality control testing.

- Environmental Science:

- Soil and sediment drying, sample preparation for analysis.

- Chemical Manufacturing:

- Solvent evaporation, curing, and polymerization processes.

- Material Science:

- Aging, durability testing, and thermal processing of materials.

- Healthcare and Medical Research:

- Sterilizing instruments and equipment, preparing samples for analysis.

Technical Data

-

BrandThermoline

-

Capacity80L - 700L

-

Models AvailableSix

-

Temperature RangeAmbient +10°C to +200°C

-

Electrical6.5A-15A/230V

-

CastorsYes

Support & FAQs

At Thermoline, we strive to supply helpful customer support to ensure that you get the most out of our products. We are committed to providing whatever support our customers need, wherever they are in the world. If you can't find your solution in the below FAQs or Knowledge Base, please contact our friendly support team.

- What is the difference between a lab oven and a drying oven?

- A drying oven is design to remove moisture from the oven chamber by introducing dry air into the chamber. These ovens are typically designed to provide a consistent and low humidity environment, which is important for drying materials effectively. Drying ovens often feature a vent or exhaust system that allows moisture to be removed from the oven workspace. Generally speaking, a regular lab oven does not exhaust air so the moist air may continue to circulate inside the chamber.

- What is the difference between Oven and Incubator?

A laboratory oven and a laboratory incubator are both commonly used in laboratory settings, but they have different purposes and functions.

A laboratory oven is used for drying, heating, or sterilising materials and is typically designed to operate at higher temperatures than a laboratory incubator. A laboratory oven typically uses air convection to circulate hot air throughout the chamber, and can be set to a specific temperature or temperature range. Ovens generally control temperatures +80°C and up.

A laboratory incubator, on the other hand, is used for maintaining a controlled, temperature-regulated environment for cell cultures, microbiological specimens, or other biological materials. Unlike a laboratory oven, a laboratory incubator is designed to maintain a temperature close to the physiological temperature of the material being incubated, usually between 30°C and 40°C. A laboratory incubator can also provide additional functions, such as humidity control and CO2 control, which are essential for the growth and maintenance of many types of cells and biological specimens.

- What is a lab drying oven used for?

A laboratory drying oven is a device used to dry, warm, or bake a variety of laboratory samples, reagents, and other materials. Some typical applications of laboratory drying ovens include:

-

Drying of moisture-sensitive samples: For example, samples such as powders, granules, and solvents can be dried to remove any residual moisture that might interfere with subsequent experiments.

-

Sterilisation of equipment and materials: By heating samples to high temperatures, laboratory drying ovens can be used to sterilise equipment and materials, reducing the risk of contamination.

-

Curing of coatings and adhesives: Some coatings and adhesives require heat to be applied to cure properly. Laboratory drying ovens can provide a controlled heating environment for these applications.

-

Thermal analysis: In some cases, laboratory drying ovens are used to subject samples to controlled temperature changes to perform thermal analysis experiments.

-

- Can the Thermoline drying oven be used for processing coal samples?

The Thermoline dry oven range is ideal for coal processing. Drying coal samples is an important step in the preparation of coal for analysis. The drying process helps to remove moisture from the coal samples, which can interfere with the accuracy of the analytical results. Here are the steps to dry out coal samples:

-

Pre-weigh the coal sample: The coal sample should be weighed before the drying process, as the weight will be used to calculate the moisture content of the coal.

-

Place the coal sample in an oven: The coal sample should be placed in a laboratory drying oven, or a similar device, and set to a temperature of about 110°C. The temperature should not exceed 150°C as this can result in a loss of volatile matter.

-

Monitor the drying process: The coal sample should be monitored regularly to ensure that it is drying evenly and to avoid overheating. This can be done by visually inspecting the sample or by using a moisture analyzer.

-

Remove the coal sample from the oven: The coal sample should be removed from the oven once it has reached a constant weight, indicating that it has been completely dried.

-

Weigh the dried coal sample: The dried coal sample should be weighed again to calculate the moisture content. The moisture content can be calculated as the difference between the weight of the wet coal sample and the weight of the dried coal sample, divided by the weight of the dried coal sample.

It's important to note that drying coal samples can take several hours to complete, and the specific conditions and procedures may vary depending on the type of coal and the intended use of the dried sample.

-

- What is the process for drying soil samples?

The process for drying soil samples in an oven is as follows:

-

Pre-weigh the soil sample: The soil sample should be weighed before drying to determine the initial moisture content.

-

Spread the soil sample on a tray: The soil sample should be spread evenly on a tray and placed in a laboratory drying oven.

-

Set the oven temperature: The temperature should be between 60°C and 105°C, depending on the soil type and the desired moisture content. It's important to avoid overheating the soil sample, as this can result in the loss of volatile components and affect the accuracy of the results. Soil particles get perfectly dry at 105°C; even the adsorbed water evaporates due to such a high temperature. But some organic soils should not be dried at 105°C because their composition changes at this temperature and some minerals might get lost. So such soils should be dried at 60–80°C

-

Monitor the drying process: The soil sample should be monitored regularly to ensure it is drying evenly. The drying time can vary depending on the amount of soil, the type of soil, and the oven temperature.

-

Remove the soil sample from the oven: The soil sample should be removed once it has reached a constant weight, indicating that it has been completely dried.

-

Weigh the dried soil sample: The dried soil sample should be weighed again to determine the final moisture content. The moisture content can be calculated as the difference between the weight of the wet soil sample and the weight of the dried soil sample, divided by the weight of the dried soil sample.

It's important to note that the specific conditions and procedures for drying soil samples may vary depending on the type of soil, the intended use of the dried sample, and the desired moisture content. It may also be necessary to repeat the drying process multiple times to ensure that the soil sample is dehydrated.

-

- Can a laboratory oven be used as an incubator?

- An oven cannot be used as a lab incubator because most ovens cannot maintain the low temperatures required for incubation purposes.