Envirotherm Temperature and Humidity Cabinet TEC

- Product Testing and Quality Control

- Research and Development

- Industrial and Manufacturing Processes

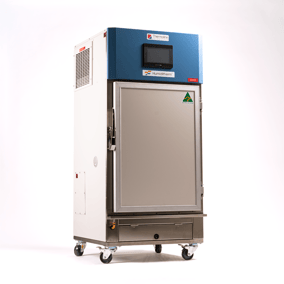

The TEC Envirotherm Cabinet series, manufactured by Thermoline, offer accurate and precise temperature and humidity control. These high-performance models can perform heating, cooling, humidification and dehumidification functions.

The range is available in two standard capacities, 460L and the double door 850L. Looking the part, our Envirotherm cabinets are constructed from stylish Colorbond steel with marine grade 316 stainless steel doors and interior.

Overview

With the ability to produce climate conditions similar to specimens' native environments, it's only natural that you'd choose our Envirotherm cabinets to store your samples. Robust and reliable, our cabinets' refrigeration systems can simulate temperatures from -30°C to +120°C with a 30–95% relative humidity range, and offer 600 watts of heat removal capacity. Whether you're conducting material testing or climate testing, you can be confident that your equipment is keeping your samples safe. Even if you need to open the door, the cabinet's fast recovery time will limit any temperature fluctuations, maintaining uniform conditions throughout the chamber enclosure.

Key Features

- Temperature and Humidity Control: Simulates temperatures from -30°C to +120°C with a 30–95% relative humidity range.

- Fast Recovery Time: Minimises temperature fluctuations when the door is opened, maintaining uniform conditions.

- Constant Airflow: Ensures conditions remain uniform throughout the enclosure, with alarms to alert if deviations from setpoints occur.

Advanced Control System

Powered by our STAR X touchscreen control system, you can easily and precisely control the cabinet's temperature, humidity, and optional carbon dioxide. The STAR X system offers:

- Real-Time Synchronisation: Allows the operator to synchronise programmed settings to real time.

- Ethernet Connectivity: Enables the operator to perform all functions via a PC.

- Data Logging: Logs the performance of the cabinet to onboard memory, holding up to 365 days of data. A live trend screen allows quick performance checks, and logged data can be downloaded to a USB flash drive for archiving or review via a PC using simple spreadsheet software like Microsoft Excel.

Sizes and Build

Australian-made, our cabinets are available in single door 460L and double door 850L capacities, so you can choose the size that suits your samples. The cabinets are built with high-quality materials to ensure durability and reliability.

Benefits

- Precision Climate Control: Ensures accurate simulation of native environments for your specimens, enhancing the reliability of your testing and storage conditions.

- High Capacity and Versatility: Available in 460L and 850L capacities, these cabinets cater to a wide range of sample sizes and types.

- Advanced Monitoring and Data Logging: The STAR X control system provides comprehensive monitoring, data logging, and easy access to performance data, ensuring optimal conditions for your samples.

- Fan-Forced Air Circulation: Both TEC cabinets feature fan-forced air circulation. This results in a temperature spatial uniformity of +/-2.0°C (unloaded) and quick recovery times after door openings.

- Options: Additional stainless steel shelving, water feed tank, viewing window solid door, CO2 control.

Environmental chambers are vital for simulating a wide range of environmental conditions to test the durability, reliability, and performance of products and materials. Here are some common uses for environmental chambers:

1. Product Testing and Development

- Stress Testing: Simulates extreme conditions such as high and low temperatures, humidity, and rapid temperature changes to test the limits of products.

- Accelerated Aging: Speeds up the aging process of products to predict their lifespan and identify potential weaknesses.

- Quality Assurance: Ensures that products meet industry standards and perform reliably under various environmental conditions before they are released to the market.

2. Material Testing

- Durability and Strength: Assesses how materials such as metals, plastics, and composites withstand different environmental stresses, including temperature fluctuations and humidity.

- Corrosion Testing: Evaluates the resistance of materials to corrosion by exposing them to humid and saline conditions.

- Thermal Cycling: Tests materials for thermal expansion, contraction, and the effects of repeated temperature changes.

3. Electronics and Semiconductor Industry

- Thermal Shock Testing: Ensures electronic components can withstand sudden and extreme temperature changes without failure.

- Humidity Testing: Tests the resilience of electronic devices to high humidity levels, which can cause malfunctions or corrosion.

- Operational Life Testing: Simulates long-term use conditions to assess the reliability and longevity of electronic products.

4. Pharmaceutical and Biotechnology

- Stability Testing: Determines the shelf life and stability of pharmaceuticals and biotech products under various environmental conditions.

- Biological Research: Provides controlled environments for growing and testing biological specimens, including cells, tissues, and microorganisms.

- Compliance Testing: Ensures that pharmaceutical products meet regulatory standards for safety and efficacy by testing them under prescribed environmental conditions.

5. Contract Compliance Testing

- Regulatory Compliance: Ensures products meet specific industry and regulatory standards, such as ISO, ASTM, or Australian Standards requirements.

- Customer Specifications: Verifies that products conform to contractual agreements and customer specifications by replicating required environmental conditions.

- Certification Testing: Provides third-party verification and certification that products meet established environmental performance standards.

- Performance Verification: Confirms that products perform as expected in real-world conditions, helping to avoid costly recalls or failures.

- Customised Testing Protocols: Develops and implements tailored testing protocols to meet unique contract requirements and ensure thorough compliance.

Environmental chambers are essential tools for a wide range of industries, providing the ability to simulate real-world conditions and ensure the reliability, safety, and performance of products and materials.

Choose Envirotherm cabinets for reliable, precise, and robust climate simulation, ensuring the safety and integrity of your valuable samples.

Specifications

- Dimensions

-

TEC-460-SD TEC-850-SD External WxDxH (mm) 840x1040x2020 1360x1040x2020 Internal WxDxH (mm) 650x650x1105 1170x650x1105 Clearance Front (mm) 820 750 Back (mm) 300 Sides (mm) 300 - Technical Specification

-

TEC-460-SD TEC-850-SD Temperature Range -30°C to +120°C Temperature Control Stability +/- 0.2°C Temperature Uniformity +/- 2.0°C Humidity Range 30% to 95%RH (within +10°C to +90°C temp range) as per Control Envelope Humidity Uniformity +/- 5%RH Heat Removal Capacity @ 10°C 600 watts 800 watts CO2 Range (Optional) Ambient to 3000 PPM (temperature limited to 60°C) Porthole Diameter 50mm Electrical 15A/230V Nominal Capacity 460L 850L Weight 250kgs 360kgs Heat Output 700 watts to 2700 watts (dependant on operating conditions) Noise Level @ 1 metre (dbA) 59 Refrigerant Type R507 - Features

-

TEC-460-SD TEC-850-SD Shelves 4 4 levels Lockable Castors ✔ ✔ Star X Touch Screen ✔ ✔ Ethernet Port ✔ ✔ Download data to USB ✔ ✔ Battery Backed-up Alarms ✔ ✔ Trough Humidification ✔ ✔ BMS ✔ ✔ Supply Line Water Filters

1x Carbon, 1x Sediment✔ ✔ Fibreglass Insulation ✔ ✔ - Safety

-

TEC-460-SD TEC-850-SD Over Current Protection ✔ ✔ Over Temperature Safety ✔ ✔ Element Safety Cut Out ✔ ✔ - Options

-

TEC-460-SD TEC-460-SD Additional Shelves Additional stainless steel shelves and clips can be supplied Heavy Duty Shelves Update to allow for higher loads on shelves (limits total number of shelves possible for use) Viewing Window Viewing window located in the door 55L Pump Water Feed Tank Pump feed water supply where mains water is unavailable CO2 Control Set Point Control of CO2 Between Ambient and 3000ppm (temperature limited to 60°C) Additional Portholes Additional 50mm port holes can be added to the side walls

Downloads

Support & FAQs

At Thermoline, we strive to supply helpful customer support to ensure that you get the most out of our products. We are committed to providing whatever support our customers need, wherever they are in the world. If you can't find your solution in the below FAQs or Knowledge Base, please contact our friendly support team.

- What is an environmental chamber used for?

- A temperature and humidity test chamber is suitable for testing your products, where they must withstand various temperatures during manufacturing, transport, storage and use. The environmental chamber allows the conditioning of test samples to a specific temperature and relative humidity conditions.

- How do you maintain humidity in a chamber?

- A refrigeration system is ideal for doing this. The evaporator coil in the chamber attracts moisture in the air, causing it to condense into water, which can then be drained away. A refrigeration system will help control temperature and humidity. Also, note that humidity is always relative to temperature; therefore, to be able to control humidity accurately and precisely, you need to control the temperature as well.

- Can I store a series of environmental chambers adjacent to one another?

- Yes, absolutely. You'll need to have enough space between cabinets to ensure that the exhaust from one does not blow into the next cabinet causing a reduction in performance. If space is an issue, please contact us about our innovative deflectors that allow chambers to be installed in close proximity to one another

- What is a temperature and humidity cabinet?

The purpose of the TRH temperature and humidity cabinet is to simulate and test the effects of various environmental conditions on products, materials, or samples in a controlled and repeatable manner.

These chambers are typically used in research and development, quality control, and manufacturing processes across a variety of industries such as electronics, automotive, aerospace, and pharmaceuticals.

- What is Dew Point?

The dew point is the temperature at which dew (condensation) forms and is a measure of atmospheric moisture. It is the temperature to which air must be cooled at constant pressure and water content to reach saturation. Dew points are expressed as a temperature. Higher dew points correlate to higher moisture content, also known as absolute humidity.

The dew point represents the lowest temperature to which air with specific temperature and relative humidity (RH) can be cooled. At the dew point, air has a relative humidity of 100%, and additional cooling produces condensation rather than lowering the air temperature.

- Do I need a water tank to supply water to the cabinet?

- You only need a 25L/55L water tank if your cabinet cannot be connected to mains water supply. If mains water supply is not possible, 25L gravity and 55L pump water feed tanks are available to supply water to the cabinet. As a rule of thumb, a cabinet running at 90%RH will deplete a 55L water tank in approximately three days.