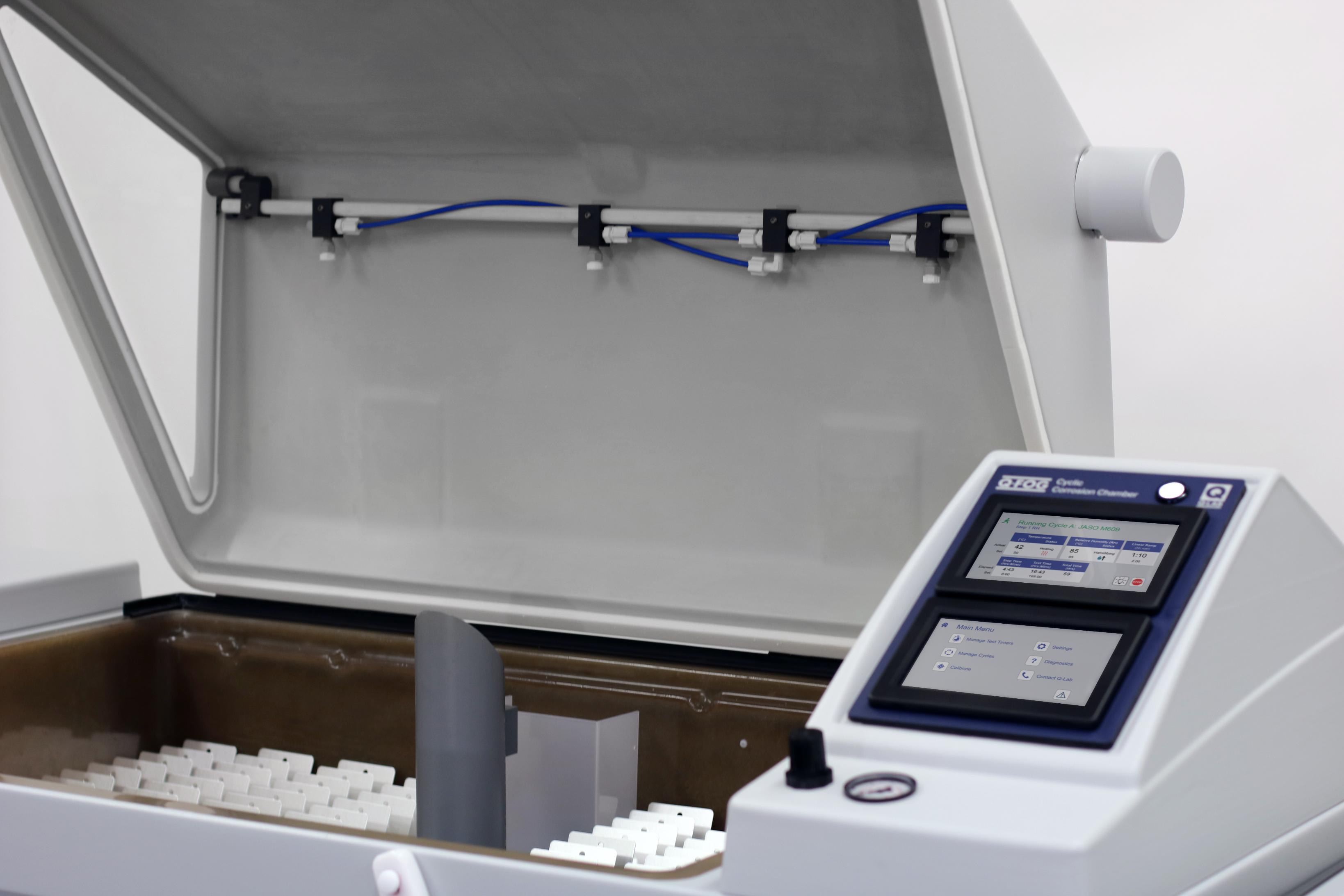

SSP/CCT Corrosion Testing Chamber Q-FOG-SSP/CCT

Cyclic corrosion testing provides the best possible laboratory simulation of natural atmospheric corrosion. Research indicates that test results are similar to the outdoors in structure, morphology, and relative corrosion rates.

The Q-Fog CCT and SSP advantages include the elimination of manually moving test specimens from one chamber to another and the laborious spraying of test specimens while reducing variability in results from excessive specimen handling.

Overview

Before the advent of cyclic corrosion testing, conventional salt spray methods (continuous salt spray at 35°C) were the standard for simulating corrosion in a laboratory setting. However, traditional salt spray tests failed to replicate the natural wet/dry cycles of the outdoors, often leading to poor correlation with real-world conditions.

Advanced Corrosion Simulation

The Q-FOG cyclic corrosion tester revolutionises corrosion testing by exposing specimens to different environments in a repetitive cycle that closely mimics outdoor conditions. From simple cycles like Prohesion, which alternate between salt fog and dry conditions, to sophisticated automotive methods involving multi-step cycles with humidity or condensation, salt spray, and dry-off phases, the Q-FOG tester can handle the most significant corrosion environments within a single chamber. Even highly complex test cycles are easily programmed with the Q-FOG controller.

Key Features and Applications

-

Versatile Testing Capabilities:

- Performs numerous accelerated corrosion tests, including continuous salt spray (ASTM B117 and ISO 9227) and Prohesion (ASTM G85 Annex 5). Prohesion testing involves fast cycling, rapid temperature changes, and a low humidity dry-off cycle using a different corrosive solution for a more realistic test, valuable for industrial maintenance coatings.

- Performs numerous accelerated corrosion tests, including continuous salt spray (ASTM B117 and ISO 9227) and Prohesion (ASTM G85 Annex 5). Prohesion testing involves fast cycling, rapid temperature changes, and a low humidity dry-off cycle using a different corrosive solution for a more realistic test, valuable for industrial maintenance coatings.

-

Continuous Salt Spray Testing:

- Widely specified for testing components and coatings for corrosion resistance. Continuous salt spray exposures are used for plated and painted finishes, aerospace and military components, and electrical/electronic systems. Tests typically follow specifications like ASTM B117 (Salt Spray) and BS 3900 F4, running at elevated temperatures without incorporating a dry-off cycle.

- Widely specified for testing components and coatings for corrosion resistance. Continuous salt spray exposures are used for plated and painted finishes, aerospace and military components, and electrical/electronic systems. Tests typically follow specifications like ASTM B117 (Salt Spray) and BS 3900 F4, running at elevated temperatures without incorporating a dry-off cycle.

-

Advanced Cyclic Corrosion Testing:

- The Q-FOG model CCT adds the flexibility of 100% humidity, ideal for automotive corrosion test methods. These methods expose specimens to repetitive cycles of salt spray, high humidity, low humidity dry-off, and ambient conditions. Originally developed as labour-intensive manual procedures, the Q-FOG CCT performs these cyclic tests automatically in a single chamber. It can also run Copper-Accelerated Acetic-Acid Salt Spray (CASS) tests such as ASTM B368 or ISO 9227 CASS.

Superior Design and Performance

-

Enhanced Fog Dispersion:

- Offers superior fog dispersion compared to conventional systems. A variable speed peristaltic pump controls the amount of corrosive solution delivered to the spray atomiser, while an air pressure regulator controls the throw distance.

- Offers superior fog dispersion compared to conventional systems. A variable speed peristaltic pump controls the amount of corrosive solution delivered to the spray atomiser, while an air pressure regulator controls the throw distance.

-

Efficient Space Utilisation:

- The internal solution reservoir maximises space and minimises maintenance. The 120L reservoir has enough capacity to run most tests for seven days or more, featuring an integral salt filter and a built-in alarm to alert the operator when the solution is low.

- The internal solution reservoir maximises space and minimises maintenance. The 120L reservoir has enough capacity to run most tests for seven days or more, featuring an integral salt filter and a built-in alarm to alert the operator when the solution is low.

-

Rapid Temperature Changes:

- Q-FOG testers can change temperatures exceptionally fast due to their unique internal chamber heater and high-volume cooling/dry-off blower. An additional air heater allows very low humidity dry-off exposures. Conventional chambers with water jackets cannot cycle rapidly due to the thermal mass of the water, nor can they produce low humidity.

User-Friendly Operation

-

Easy Specimen Mounting and Programming:

- Designed for easy specimen mounting and simple programming to cycle between four conditions: Fog, Dry-Off, 100% Humidity (Model CCT only), and Dwell. A built-in microprocessor controls test conditions, time, and temperature.

- Designed for easy specimen mounting and simple programming to cycle between four conditions: Fog, Dry-Off, 100% Humidity (Model CCT only), and Dwell. A built-in microprocessor controls test conditions, time, and temperature.

-

Intuitive User Interface:

- Features dual, full-colour touch screens for easy user programming and operation.

The Q-FOG Cyclic Corrosion Tester is a powerful, versatile, and user-friendly tool for advanced corrosion testing. It ensures reliable and accurate simulation of real-world conditions, making it an essential instrument for laboratories and industries focused on material durability and performance evaluation. Choose the Q-FOG tester for advanced corrosion testing to achieve precise and dependable results.

Specifications

- Features

-

SSP CCT CRH Sizes Available 600 L / 1100 L 600 L / 1100 L 600 L / 1100 L Dual full-color touch-screen displays ✔ ✔ ✔ Internal 120 liter salt solution reservoir ✔ ✔ ✔ Monitoring window & internal viewing light ✔ ✔ ✔ Internal chamber heaters for fast temperature cycling ✔ ✔ ✔ Salt Fog Function (atomizing mist) ✔ ✔ ✔ Dry Function (< 30% relative humidity) ✔ ✔ ✔ Humid Function (95-100% relative humidity) X ✔ ✔ RH Function (relative humidity control via Air Preconditioner) X X ✔ Wall Wash Kit (for compliance with Renault ECC1) X X Optional Stationary Shower Module (with self-cleaning spray nozzles) X X Optional Top-Mounted Swaying Shower (with self-cleaning spray nozzles) X X Optional Rapid Ramp Heaters (for fast temperature/RH transitions) X X Optional Access Port (100 mm diameter for wiring access in chamber) Optional Optional Optional External Fog Collection Cylinders Optional Optional Optional - Dimensions

-

SSP600/CCT600 SSP1100/CCT1100 External WxDxH (mm)

lid closed1890 × 1130 × 1220 2250 × 1290 × 1270 Internal WxDxH (mm)

max, excluding lid1100 × 710 × 730 1470 × 870 × 720 WxDxH (mm)

min, excluding lid1080 × 610 × 730 1440 × 770 × 720 - Technical Specifications

-

SSP600/CCT600 SSP1100/CCT1100 Chamber Size Volume (including lid) ~600 liters (21 ft³) ~1100 liters (39 ft³) Volume (excluding lid) ~500 liters (18 ft³) ~900 liters (32 ft³) Built-in salt solution reservoir ~120 liters (32 gal) ~120 liters (32 gal) Chamber Temperature Range Fog or Dwell 20-60 °C 20-60 °C Dry-Off 20-70 °C 20-70 °C Humid/RH 20-60 °C 20-60 °C Specimen Panel Capacity 100 × 300 mm 120 (96 for -T models) @ 8 racks 190 (160 for -T models) @ 10 racks 75 × 150 mm 170 (160 for -T models) @ 10 racks 252 (240 for -T models) @ 12 racks Specimen Load Capacity Each panel rack 113 kg (250 lbs) max Each hanging rod 45 kg (100 lbs) max Each mounting grate 272 kg (600 lbs) max Total chamber (distributed) 544 kg (1200 lbs) max Inlet Water Purity >200 kΩ∙cm;

<5 μS/cm

<2.5 ppm TDS>200 kΩ∙cm;

<5 μS/cm

<2.5 ppm TDSInlet Water Pressure 0.2-3.8 bar (3-56 psi) 0.2-3.8 bar (3-56 psi Water Consumption 2 L/h max 2 L/h max Drain 32 mm (1-¼ in) tubing with trap Air Vent 102 mm (4 in) inner diameter min Compressed Air Maximum volume 1.7 L/s (3.5 cfm) 1.7 L/s (3.5 cfm) Pressure 3-10 bar (40-150 psi) 3-10 bar (40-150 psi) Weight 224 kg (494 lbs) 269 kg (594 lbs) Electrical Requirements 208 V 1-Φ @ 16 A 1-Φ @ 20 A 230 V 1-Φ @ 14 A 1-Φ @ 18 A Lab Recommendations Temperature (°C) 23 ± 5 °C Relative Humidity (%) 50 ± 25%

Downloads

Support & FAQs

At Thermoline, we strive to supply helpful customer support to ensure that you get the most out of our products. We are committed to providing whatever support our customers need, wherever they are in the world. If you can't find your solution in the below FAQs or Knowledge Base, please contact our friendly support team.

- What is Cyclic Corrosion testing?

- Cyclic corrosion testing is intended to be a more realistic way to perform salt spray tests than traditional, steady-state exposures. Because actual atmospheric exposures usually include both wet and dry conditions, it makes sense to pattern accelerated laboratory tests after these natural cyclic conditions. Research indicates that, with cyclic corrosion tests, the relative corrosion rates, structure and morphology are more similar to those seen outdoors. Consequently, cyclic tests usually give a better correlation to outdoors than conventional salt spray tests. They effectively evaluate various corrosion mechanisms, including general, galvanic, and crevice corrosion.

Cyclic corrosion testing is intended to produce failures representative of the type found in corrosive outdoor environments. CCT tests expose specimens to different environments in a repetitive cycle. Simple exposures like Prohesion may include cycling between salt fog and dry conditions. More sophisticated automotive methods call for multi-step cycles incorporating immersion, humidity, condensation, salt fog, and dry-off. Initially, these automotive test procedures were designed to be performed by hand. Laboratory personnel manually moved samples from salt spray chambers to humidity chambers to drying racks, etc. More recently, microprocessor-controlled chambers have been used to automate these exposures and reduce variability. - Can the Q-Fog tester control relative humidity?

- The Q-FOG model CRH can ramp to and maintain a defined RH value and temperature through the use of an air preconditioner, an air control module, and special atomizing humidification nozzles. Deionized (DI) water is required for proper operation. The Q-FOG model CCT has the capability of 95-100% humidity control.

- What specimen mounting options are available with the Q-Fog?

- Standard test panel racks are available to accommodate flat specimens, such as Q-PANEL standard substrates. Odd-shaped parts (e.g. large, three-dimensional specimens) can be mounted on special 20 mm hanging rods. A rack-level or diffusion-level grate kit may be used for extremely large or heavy three-dimensional objects (such as metal wheel rims, engine parts, etc.).

- What if my test requires quicker heat up times?

- Rapid Ramp Heater capability enables the performance of some corrosion tests that have very fast transition times.

- What is Dew Point?

The dew point is the temperature at which dew (condensation) forms and is a measure of atmospheric moisture. It is the temperature to which air must be cooled at constant pressure and water content to reach saturation. Dew points are expressed as a temperature. Higher dew points correlate to higher moisture content, also known as absolute humidity.

The dew point represents the lowest temperature to which air with specific temperature and relative humidity (RH) can be cooled. At the dew point, air has a relative humidity of 100%, and additional cooling produces condensation rather than lowering the air temperature.

- Why is Relative Humidity important in laboratory corrosion testing?

Corrosion is caused when a metal is in contact with water and an electrolyte, such as a salt. In this corrosive environment, metals react to form metal oxides. Except for noble metals such as gold, silver, and platinum, all metals exist as oxides in the environment. Corrosion is effectively nature’s way of returning refined metals back into their natural state.

Although this concept is simple, the practice of simulating outdoor corrosion in the laboratory is very difficult. Multiple oxides can form as a result of complex multi-step reactions that are dependent on specific environmental conditions. Environmental cycling of temperature and moisture is the main reason that outdoor corrosion mechanisms are so complex. In weathering, we often talk about dew (condensation) and rain as they relate to moisture. In corrosion, there is another term related to moisture, called deliquescence. This is the phenomenon where any salt will form a liquid solution when the environment exceeds a relative humidity threshold. This threshold is known as the deliquescence relative humidity (DRH) and varies for different salts.

Deliquescence of salts can affect strongly the time of wetness of materials, which plays a major role in the corrosion experienced by specimens. To address this, temperature and humidity transitions specified in modern corrosion test cycles are usually controlled to ensure that the time above the DRH during a transition is consistent, regardless of which tester is used to run the cycle. Without controlled transitions, repeatability and reproducibility drop considerably.