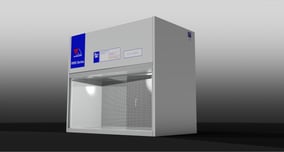

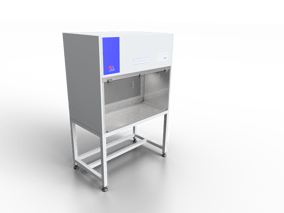

Ultrasafe Class II Biological Safety Cabinets Ultrasafe

The Australian Made Ultrasafe Class II Biological Safety Cabinet features an ergonomically-designed operating window that slants away from the operator. A feature which greatly enhances the ease of use without compromising the clean integrity of the work zone.

Add to this a wide range of accessories, and the proven reliability of the Email and Clyde-Apac brands and the Ultrasafe represents excellent value for money in the Laminar Flow market.

Overview

Ultrasafe cabinets utilise digital technology to maintain constant airflow during normal filter loading or temporary obstructions from foreign objects. Pressure sensor monitoring ensures safe and uniform airflow across the entire work surface. Independent alarm systems immediately alert the user to any airflow obstruction. An air barrier across the work access opening into the sump reduces potential risks to personnel from airborne contaminants in the work zone.

Key Features

- Digital Airflow Control: Uses digital technology to maintain constant airflow, ensuring safety and uniformity.

- Pressure Sensor Monitoring: Ensures safe and uniform airflow, with immediate alerts for any obstruction.

- Air Barrier: Reduces risks from airborne contaminants with an air barrier at the work access opening.

- Advanced Airflow Design: In Class II models, airflows mix in the sump before recirculation via a return air plenum to the top housing. Exhaust air passes through a HEPA filter before returning to the lab.

- Independent Fan/Filter Arrangements: Allow independent adjustment to maintain an effective air barrier.

- Microprocessor Control: Controls blower motor speed and allows fingertip control of functions and status, including cabinet performance, current status, and boost mode.

- User-Friendly Controls: Low-voltage electronic touch controls with an easy-to-read digital display.

- Enhanced Visibility: Transparent side UV-resistant safety glass maximizes light and visibility inside the cabinet.

Ergonomic Design

The new Ultrasafe cabinet is designed with a sloping front, work tray options, and an electric height-adjustable stand, offering significantly improved ergonomics compared to traditional cabinets. The 200mm front working aperture ensures safety and sample containment while reducing noise levels.

Safety and Efficiency

- Dual Fan Design: Ensures guaranteed safety; if one fan fails, minimal protection is still maintained.

- HEPA Filters: Independent H14 HEPA supply and exhaust filters provide 99.995% typical efficiency for particle sizes of 0.1 to 0.3 microns.

- Backup Battery: Maintains alarm functions for airflow, power, and pressure in the event of a power failure.

- High-Quality Work Surfaces: Scratch-free stainless steel work surfaces are available as single or segmented modules, easy to clean or autoclave. Indented work modules trap spilled liquids.

Accessories & Options

- Service taps (air, CO2, etc.)

- Vacuum tap (disc filter holder)

- Extra power outlet (1 x power outlet supplied as standard)

- Decontamination panel

- Floor stand, semi-adjustable (height to order)

- Electronically-controlled, height-adjustable floor stand

- Gas tap (solenoid-interlocked)

- Front, top, left, or right exhaust options available

Ultrasafe cabinets offer advanced features, ensuring safety, reliability, and ergonomic comfort for laboratory personnel.

Class II Biological Safety Cabinets (BSCs) are essential in various laboratory and clinical settings to provide both personnel and environmental protection when working with biohazardous materials. Here are the primary uses and applications for Class II BSCs:

Laboratory Research:

-

Microbiological Research:

- Handling of pathogenic microorganisms, including bacteria, viruses, fungi, and parasites.

- Preparation of cultures and inoculation of media.

-

Cell and Tissue Culture:

- Safe manipulation of eukaryotic cells, tissues, and organ cultures.

- Prevention of cross-contamination between different cell lines.

-

Genetic Research:

- Working with recombinant DNA, genetically modified organisms (GMOs), and gene editing tools such as CRISPR.

Clinical and Medical Applications:

-

Diagnostic Testing:

- Preparation and analysis of patient specimens, including blood, urine, and tissue samples.

- Molecular diagnostic techniques, such as PCR and qPCR.

-

Pharmaceutical Testing:

- Compounding sterile preparations, including injectables and intravenous (IV) solutions.

- Quality control testing for pharmaceutical products.

Public Health and Epidemiology:

- Infectious Disease Research:

- Study and analysis of infectious agents to understand disease mechanisms and develop treatments or vaccines.

- Study and analysis of infectious agents to understand disease mechanisms and develop treatments or vaccines.

- Vaccine Development:

- Production and testing of vaccines in a controlled, contamination-free environment.

Industrial Applications:

-

Biotechnology:

- Production of biopharmaceuticals, including monoclonal antibodies, proteins, and enzymes.

- Fermentation and bioprocessing involving live cultures.

-

Food and Beverage Industry:

- Microbiological testing to ensure the safety and quality of food and beverage products.

Educational and Training Purposes:

- Academic Laboratories:

- Training students in microbiological techniques and safe handling of biohazardous materials.

- Conducting research projects under controlled conditions.

Class II Biological Safety Cabinets are indispensable tools in any setting that requires the safe handling of biohazardous materials, ensuring the highest standards of safety and contamination control.

Technical Data

-

BrandAES Environmental

-

Models AvailableThree

-

Sizes900mm/1200mm/1800mm

-

Electrical2A/230V

-

Filter TypeHEPA

-

Complies WithAS 2252.2

Support & FAQs

At Thermoline, we strive to supply helpful customer support to ensure that you get the most out of our products. We are committed to providing whatever support our customers need, wherever they are in the world. If you can't find your solution in the below FAQs or Knowledge Base, please contact our friendly support team.

- What is a Class 2 Biological safety cabinet?

A Class 2 Biological Safety Cabinet (BSC) is a type of laboratory equipment used to protect the user, the sample, and the environment from exposure to biological materials that may be hazardous. Class 2 BSCs are designed to provide a barrier between the user and the sample and to contain any accidental releases or spills.

Biological safety cabinets are the primary barrier against exposure to aerosols that may be produced from common microbiology procedures. Room air is drawn in through the front grill of the cabinet and is developed for sterile material handling.

Class 2 BSCs are designed for use with low-risk biological materials, such as bacteria or viruses that are not highly infectious or dangerous. They use a combination of physical and airflow barriers to provide a controlled environment for handling biological materials.

- What Australian Standards do I need to know for the installation and maintenance of a Class II BSC?

- AS 2252.4 - 2010: Controlled environments Part 4: Biological safety cabinets Class I and II – Installation and use. This Standard is an excellent source of reference when looking to organise BSC installation in the laboratory. AS 2252.2 – 2009: Controlled environments Part 2: Biological safety cabinets Class II – Design. The Standard states that periodic critical performance tests of the cabinet shall be conducted at least annually and on any change to cabinet position and function.

- Where are the clean air cabinets supplied by Thermoline manufactured?

- All of the cabinets we supply are Australian Made by AES Environmental. AES has several manufacturing locations in Australia, and all of the Laminar Flow and High-Efficiency Filtration products are produced in their Minto, NSW facility.

- Can Thermoline arrange installation and commissioning of my cabinet?

- Yes. Our suppliers have service divisions in most Australian states and territories and relies on qualified partners for other geographical locations. Each team is capable of providing on-site installation and NATA certification.